For newer model bikes, there are aftermarket offset crankpin. which mostly made for fourstoke bikes. only a few for 2 strokes. And the ones that i know that has it was yamaha 125z and yamaha rxz. with ofset up to 1.5mm only. Since my bike is old model and there no market for racing parts as such for the model.

My initial project fails since my customized offset crank pin is not strong enough. The material used to make it was not as strong as that original crank pin. The performance outcome was superb but it didn’t last. Went a few rounds on d road with it and it wore off by 0.5mm. Doesn’t sound much but enough to make my engine sounds like and engine with broken bearings. Or worse. Then I have to dismantle my engine again and install d stock crank again. :S. cost me quite some bucks but it’s part of the R&D for this.

These are the plans for the failed crank pin

Initial planing.

Done

On one side of the crank

Grind the bottom conrod for clearance

Half circle bearings

Conrod on d pin

Custom made 1.5mm metal spacer

Spacer done and on the block

installed half crank in the crankcase to chek for clearance and fittings

2mm increase of stroke

0.5mm clearance from d wall

The plan was a failure. But i can tell that it performs damn awesome. coz before it failed. i can tell that it was much better in response and d feel of d engine. 4th gear was as if im still in 2nd gear when riding Too bad d material didnt last. Few rounds and d custom crank pin worn off by 0.5mm. Heavy knocking sound in d engine and cant ride with that kinda engine condition. So i have to install the stock crank again.

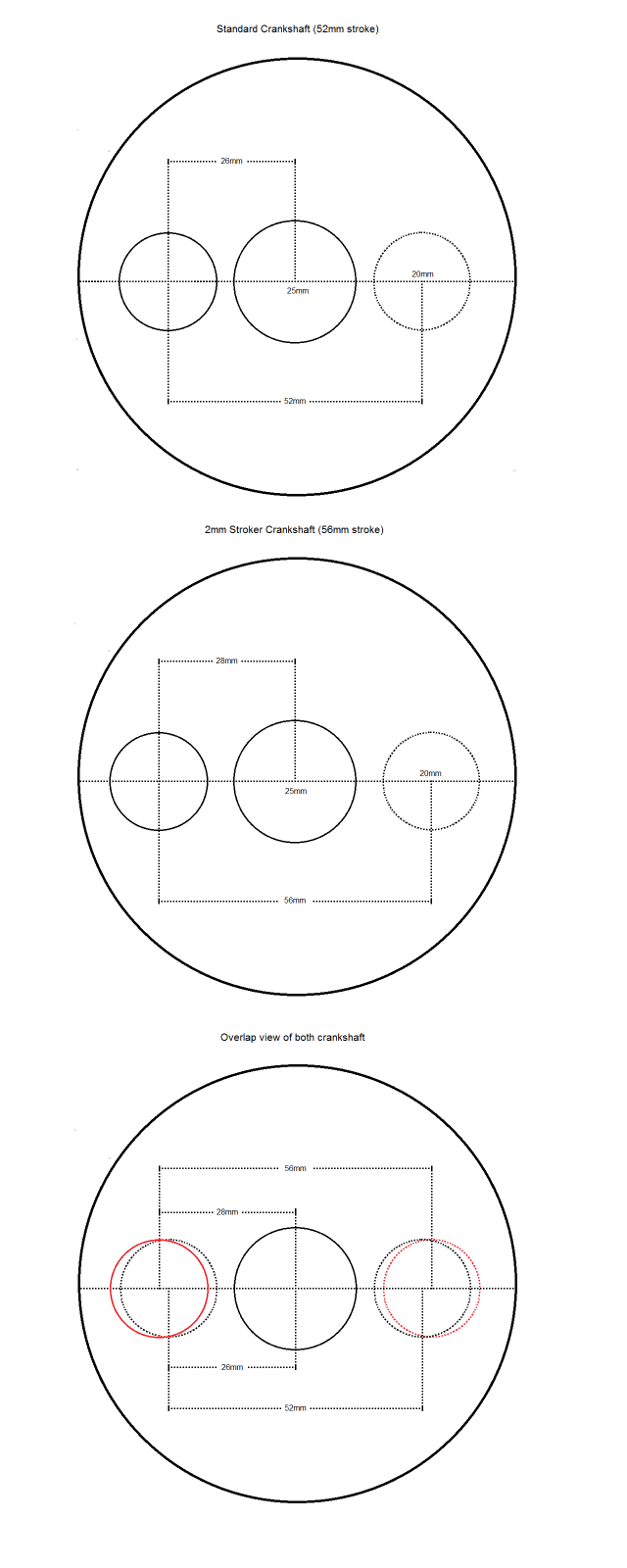

But recently i found out a new method of increasing the stroke instead of making an offset crank pin. I figured that closing the original hole of the crankpin on the crankshaft and redrill a new hole that adds d stroke by 2mm as well. the below pic explains it.

I drew this plan to show how the stoke of the crank is counted. and to see how to relocate the crankpin hole.

example 1:

example 2: notice d crankpin on both crankshafts

This process takes time and money. So i cant really make this as soon as i wish. It depends on my budjet. The outcome of my plan will be superb and performance wise will be insane. Theoretically, coz by increasing stroke, it increases the displacement of the engine and d torque and so thus the power. From 52mm stroke to 56mm stroke is a big improvement in displacement and performance for my bike. since im using a racing cylinder block with 56mm piston, the finish stroked crankshaft of 56mm will make my engine as a "squared engine" which means that i have my stroke and piston size same in measurement of 56mm each. This means my bike will have power in Low RPM range, Mid RPM range, and High RPM range. all in one pakkage. having "Over Bore Engine" will provide better Mid RPM range and High RPM range only. While "Over Stroke Engine" will provide Low RPM to Mid RPM only.

Im going to do an over bore as well soon. with piston size 60mm. increases displacement of the engine and performance. Originally my engine has 52mm stroke and 52mm bore which means my displacement was 110.4cc. Now im using 56mm piston which means 128.0cc. Once i have my stroked crank will be 56mm stroke and 56mm bore equals to 137.9cc. and once i get my 60mm piston installed at that moment the displacement will be 158.3cc. Big leap from 110.4cc to 158.9cc. In 2 stoke it is a very big difference. and it will be mad performance for a small bike with a big displacement engine on it.